What are the latest Polymer capacitor manufacturing processes?

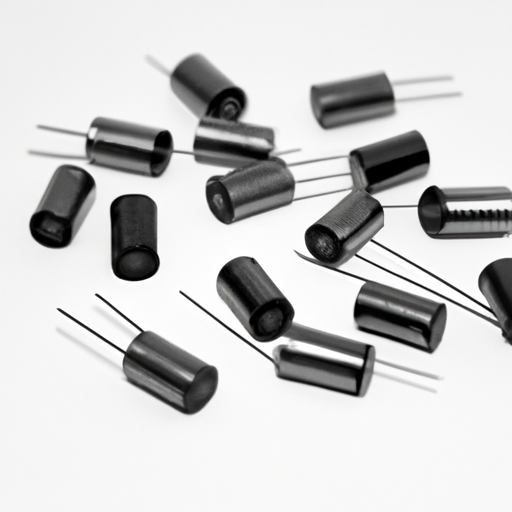

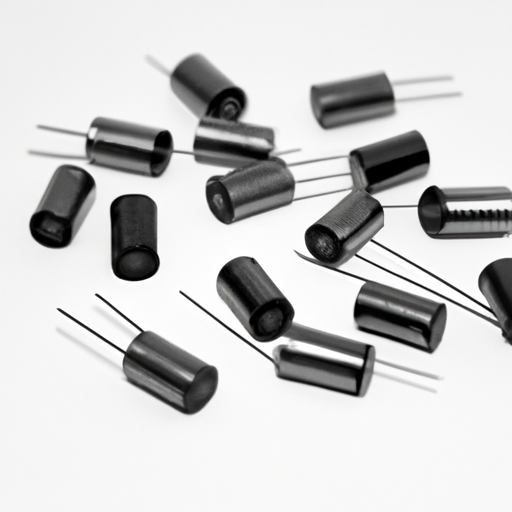

Polymer capacitors are a type of electrolytic capacitor that uses a conductive polymer as the electrolyte instead of a liquid electrolyte. These capacitors offer several advantages over traditional electrolytic capacitors, including lower ESR (Equivalent Series Resistance), longer lifespan, and better stability over a wide range of temperatures. In recent years, there have been significant advancements in the manufacturing processes of polymer capacitors, leading to improved performance and reliability. In this article, we will explore some of the latest manufacturing processes used in the production of polymer capacitors.

Another important aspect of polymer capacitor manufacturing is the electrode design and construction. The electrodes in polymer capacitors are typically made of a conductive material such as aluminum or tantalum, coated with a layer of conductive polymer. Manufacturers are continuously refining the electrode design to improve the capacitor's performance and reliability. For example, some manufacturers are using advanced deposition techniques such as sputtering or atomic layer deposition to create thin, uniform electrode layers with high conductivity and low resistance.

In addition to materials and electrode design, the manufacturing process itself plays a crucial role in the performance of polymer capacitors. One of the latest advancements in manufacturing processes is the use of automated assembly and testing equipment. Automated equipment allows for precise control over the manufacturing process, leading to higher consistency and reliability in the final product. For example, automated equipment can ensure that the electrodes are uniformly coated with the conductive polymer, leading to lower ESR and better performance.

Furthermore, manufacturers are also implementing advanced quality control measures to ensure the reliability of polymer capacitors. For example, some manufacturers are using advanced testing techniques such as accelerated aging tests and thermal cycling tests to evaluate the performance of polymer capacitors under various operating conditions. These tests help manufacturers identify any potential issues with the capacitors and make necessary improvements to enhance their reliability.

Overall, the latest advancements in polymer capacitor manufacturing processes have led to significant improvements in performance, reliability, and lifespan. Manufacturers are constantly researching and developing new materials, technologies, and manufacturing techniques to create polymer capacitors that meet the growing demands of modern electronic devices. With continued innovation and investment in research and development, polymer capacitors are expected to play an increasingly important role in the electronics industry in the years to come.

Polymer capacitors are a type of electrolytic capacitor that uses a conductive polymer as the electrolyte instead of a liquid electrolyte. These capacitors offer several advantages over traditional electrolytic capacitors, including lower ESR (Equivalent Series Resistance), longer lifespan, and better stability over a wide range of temperatures. In recent years, there have been significant advancements in the manufacturing processes of polymer capacitors, leading to improved performance and reliability. In this article, we will explore some of the latest manufacturing processes used in the production of polymer capacitors.

Another important aspect of polymer capacitor manufacturing is the electrode design and construction. The electrodes in polymer capacitors are typically made of a conductive material such as aluminum or tantalum, coated with a layer of conductive polymer. Manufacturers are continuously refining the electrode design to improve the capacitor's performance and reliability. For example, some manufacturers are using advanced deposition techniques such as sputtering or atomic layer deposition to create thin, uniform electrode layers with high conductivity and low resistance.

In addition to materials and electrode design, the manufacturing process itself plays a crucial role in the performance of polymer capacitors. One of the latest advancements in manufacturing processes is the use of automated assembly and testing equipment. Automated equipment allows for precise control over the manufacturing process, leading to higher consistency and reliability in the final product. For example, automated equipment can ensure that the electrodes are uniformly coated with the conductive polymer, leading to lower ESR and better performance.

Furthermore, manufacturers are also implementing advanced quality control measures to ensure the reliability of polymer capacitors. For example, some manufacturers are using advanced testing techniques such as accelerated aging tests and thermal cycling tests to evaluate the performance of polymer capacitors under various operating conditions. These tests help manufacturers identify any potential issues with the capacitors and make necessary improvements to enhance their reliability.

Overall, the latest advancements in polymer capacitor manufacturing processes have led to significant improvements in performance, reliability, and lifespan. Manufacturers are constantly researching and developing new materials, technologies, and manufacturing techniques to create polymer capacitors that meet the growing demands of modern electronic devices. With continued innovation and investment in research and development, polymer capacitors are expected to play an increasingly important role in the electronics industry in the years to come.